- Important Considerations

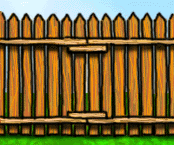

- What's Available?

- Fence Terminology

- Site Layout

- Dealing With Slopes

- Digging Postholes

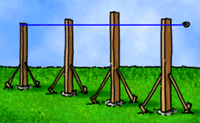

- Setting The Posts

- Cutting Posts To The Proper Height

- Attaching Panels

- Building A Gate

- Fence Finishing And Maintenance

- Important Considerations

- There are many reasons for building a fence--security, noise reduction, and boundary definition. Fences are even used to screen unsightly areas. All of these factors will affect your choice of fence type and style. Before planning and purchasing your fence materials, ask yourself these questions.

- What will the function of the fence be?

- What style will best accomplish this function?

- What style and material will blend with my landscaping and the architectural feel of my home?

- Since you may not be the only one who is affected by your fence, it's a good idea to discuss your plans with any neighbors whose property lies along your proposed fence line. If possible, an agreement with your neighbor is ideal since it could allow sharing of costs for building and maintenance. Any agreement should be in writing and recorded to settle any potential disputes with future property owners. If you cannot or decide not to go into an agreement, take every precaution to make sure your fence is on your property, and at least consider that your neighbor will have to look at it too.

- You'll need a copy of your deed and title to get the exact boundaries of your property. If you are unsure of your boundaries, have an accurate survey made to ensure that your fence will lie on your property. Check for easements in your deed (an easement is a right-of-way granted to another property owner or utility company which may limit the design and location of your fence). Avoid digging in areas which have underground lines by checking with your utility or cable company before you begin. You could be liable for damage to any such lines.

- Also check local zoning laws which can determine the maximum height of your fence, as well as how far it has to be set back from your property line and how much of your lot may be covered by structures. If you live in an historic district or a subdivision, check with your neighborhood association as you may need approval before proceeding with your plans.

- You can apply for a variance with local building authorities if your fence plans conflict with local regulations. Don't begin construction if you are in violation of any ordinances, easements or building codes. If you do, your fence could be torn down at a later date for violations.

- What's Available?

- There are many different fence panels available which may differ in the details. Basically, however, there are three major preassembled fence panel styles to choose from:

- Solid --This style, when used as containment fencing, allows for complete privacy. It is commonly used to surround swimming pools and between property lines. It may also be used to conceal unsightly areas or to hide a major roadway from view. These fences are generally 4-6' tall to serve these purposes, and use very closely spaced pickets which may vary in style from a basic dog-ear style to a pointed top or elaborate design.

- Spaced Picket --This is ideal for keeping children and/or pets in and defining boundaries while achieving a distinctive look and aesthetic appeal. These fences are generally shorter, 4' tall or less, and do not completely block the surrounding view.

- Shadowbox --This style uses alternating panels across the back and front to give the fence the same look on both sides. This is an ideal "neighborly" fence style since a person on the other side will have a pleasant view of it as well. These fences are generally taller, usually around 6'.

- Make Sure It'll Last

- To build a durable fence that will last for years to come, pay special attention to the materials you use. Select treated lumber approved for "ground contact" especially for posts but for above-ground use as well. With pressure treatment, less expensive woods such as pine and spruce can last as long as cedar and redwood. No matter what kind of wood you choose, pressure treated or not, it's always a good idea to use a paint, stain or waterproofing sealer after you finish your fence. Use weather-resistant galvanized nails and exterior screws. Finish with rust-proof caps on post tops or cut the top at an angle to shed water.

Fence Terminology

- Posts

Tools & Materials

- String (for staking boundaries)

- Level

- Concrete mix

- Galvanized nails or stainless steel screws at least 2 1/2 times

longer than the thickness of the rails on the panel - Drill

- Tape Rule

- Site Layout

- Taking time to lay out the fence carefully can save time and frustration in the long run. An incorrect measurement now could result in problems later. Make provisions for the widths of the fence panels and gates so you won't end up with odd sized bays that can complicate installation. Some types of preassembled panels like grapestake, shadowbox and picket can be cut to fit smaller bays if you end up with an odd-sized section. Other types, like panels with horizontal woven elements, for example, would be difficult if not impossible to cut to size. Take extra special care if you are using these types of panels.

- Stake out your fence line from beginning to end, including corners and any gates.

- Tie a string tautly between corner post locations. This will define the line along which the line posts will be placed.

- Be sure to measure your panels before performing this next step because all of them are not exactly 4, 6 or 8' long. Then, using the same measurement as the length of your panels, stake out the line post locations. To do this, measure "on center" from each corner post (from center to center of each post instead of from the edges) along the layout lines. Mark each post location with a stake. Ensure that the stakes are touching the layout string so the posts will be in line. Don't forget to take gates into account at this stage. Since you will be custom building your gates, their widths can vary. This allows some flexibility in layout even though you're working with preassembled fence panels.

- Dealing With Slopes

- Fences may be installed on slopes using one of two methods. The parallel method has the fence running parallel to the slope. Since this method requires that the fence be constructed to conform to the slope, it cannot be accomplished using preassembled fence panels. The step method, on the other hand, is ideal for fence panel installations. In this case, the fence gradually "steps" up the slope so that each bay section is the same length and the rails are level instead of parallel to the slope.

- When staking out line posts on a slope for a step method installation, you will need a true horizontal measurement for post placement. Do not measure parallel to the ground slope. To obtain the proper layout, do the following: Measure from the previous stake while holding the tape horizontally. Use a 2x4 to extend from the proper tape measurement to the ground to locate the placement of the stake. Properly executed, the tape will form a right angle with the 2x4. (See graphic at right.)

- Continue this measuring method for the rest of the slope until the ground levels out.

- Digging Postholes

- Using a posthole digger or power auger, dig the holes 10-12" wide and 6" inches deeper than needed. A good rule of thumb is to put 1/3 of the post in the ground. Main and gate posts should be set 6" deeper for extra strength. Keep the height of your fence panels in mind when digging your postholes.

- Backfill each hole with 6" of gravel to drain water away from the bottom of the post.

- Setting The Posts

- Install end and corner main posts first. Tie a string between these posts along the fence line. This will establish a reference so you can make sure the line posts are set in line.

- Brace the posts using 4' sections of 2x4's nailed to the post diagonally and then nailed to stakes in the ground. This will keep them straight while the concrete sets.

- Check each post to make sure it's plumb using a level on two adjacent sides.

- Fill holes with concrete mix and follow all package instructions. Prod the mix with a stick while filling to reduce any air pockets.

- Overfill holes at the top. Using a trowel, slope the concrete away from the post to prevent water from collecting around it. If you want to conceal the concrete, pour it to within a few inches of the top of the hole and cover it with soil after the concrete has set.

- Before concrete sets, check plumb and alignment again and make any necessary adjustments.

- Allow concrete to set 24-48 hours before installing fence panels.

- Cutting Posts To The Proper Height

- When setting posts on a slope, set them so they're taller than you need for the panel so you can cut them to height just before the panels are hung. Some people prefer to use this method for all of their posts.

- An easy way to make your post heights uniform on level ground is to run a string at the desired height from corner post to corner post keeping it taut. Mark each line post at the string line and cut off the tops of the posts.

- Attaching Panels

- You will need help when attaching the fence panels, so plan appropriately.

- Place each panel between the posts so that the ends of the panel come to rest in the center of the posts. Preassembled fence panels have a top and bottom support rail between the frame to which the pickets are attached. Use a level to align the top rail horizontally.

- Use stainless screws or 18d to 20d galvanized nails to attach the panel to the post. Attach the panel through the top and bottom rails. Have someone support the posts while you're nailing.

- If it is necessary for some reason that two panels must butt together between posts (perhaps there is something in the way that prevents the setting of a post in the appropriate place, for example), attach a 3' cleat across the joints of the rails to provide additional support.

- Building A Gate

Tools & Materials

- Since the gate will endure more use and wear than any other part of the fence, use secure gate posts, strong hardware, and a well-built and braced frame. If your gate opening is wider than 5', you should make your gate with two doors of equal width. Together, the two should span the distance of the gate opening. Each section should be attached to a post and then latched in the center. This design provides greater stability than using a single 5' wide gate which might be too heavy on the hinges and can also be awkward to use.